What is centrifugal casting?

- Share

- publisher

- Lisa

- Issue Time

- Jun 18,2019

Summary

Centrifugal Casting is the process in which molten metal is poured into a spinning die that rotates at several hundred rpm. YX Machinery provide centrifugal casting like bushes & castings of Gunmetal,Bronze,Phosphor Bronze,Aluminium,Cast Iron, Cylinder liners of Alloys of Cast Iron

What is centrifugal casting?

What is centrifugal casting?

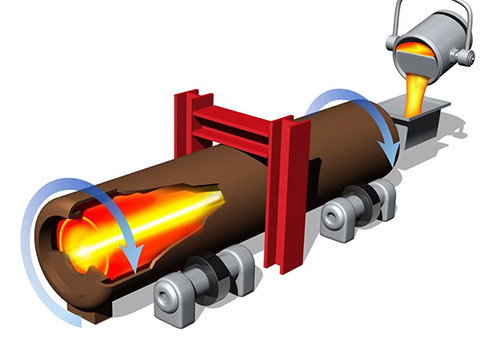

Centrifugal Casting is the process in which molten metal is poured into a spinning die that rotates at several hundred rpm. The metal is centrifugally spun towards the inside die wall, where it cools and solidifies. The resulting casting is a fine grain tube that can be subsequently machined to produce a variety of cylindrical parts. During the centrifuging process, the pure metal is spun to outside of the casting, leaving any impurities on the inside diameter, which are then machined away. The centrifugal process produces a more consistent microstructure and typically has fewer issues with porosity than static casting.

Centrifugal steel castings, iron castings, and nickel alloy castings are used extensively in the automotive, power generation, petrochemical, oil & gas, mining, and drilling markets. As centrifugal casting is a form of die casting, the tooling expense associated with sand casting or investment casting is largely eliminted.

Product advantages

(1)with good metal retraction and dense and the mechanical properties. Centrifugal casting roughcast will not be cracks, scum stoma and sandstone in its inner and outer surface

(2) The sleeve increased plasticity and toughness after quenching & tempering, and Improve yield strength and tensile strength, reduce elongation.

(3)Use the special tool to process end face, taper and the outer circle according to inner hole to ensure beating of the taper, the concentricity and cylindricity of the steel spool.

Material composition comparison

Elements Materials | C | Si |

Mn

|

Cr

|

Ni

|

Mo | V | S,P |

Introduction

|

|

|

Low plasticity and toughness, low temperature resistance.

|

||||||||

|

|

|

High strength, toughness and hardenability, high temperature resistance.

|

|||||||

|

|

|

Better than 35CrMo performance, and can meet the general use requirements.

|

|||||||

High strength and toughness, high temperature resistance, high procurements cost | |||||||||

High strength and toughness, high temperature resistance, high procurements cost |